Aluvindo’s Product & Features

Our Capabilities

We are focused on the requirements of our customers, a significant investment has been made in processing and fabrication facilities, including four extrusion presses and one of the largest extrusion press; the 2300 US TON Constant Speed Aluminum Extrusion Press.

Fabrication facilities include; computerized fine tolerance cut to length, CNC extrusion machine center and large machining bed and a CNC rolled product router; with giant sized bed. Cutting thickness up to 25mm, allow us to supply material closer to a final form, providing the option of bespoke sizes and finishes previously unavailable, creating a real opportunity for a one-stop-shop.

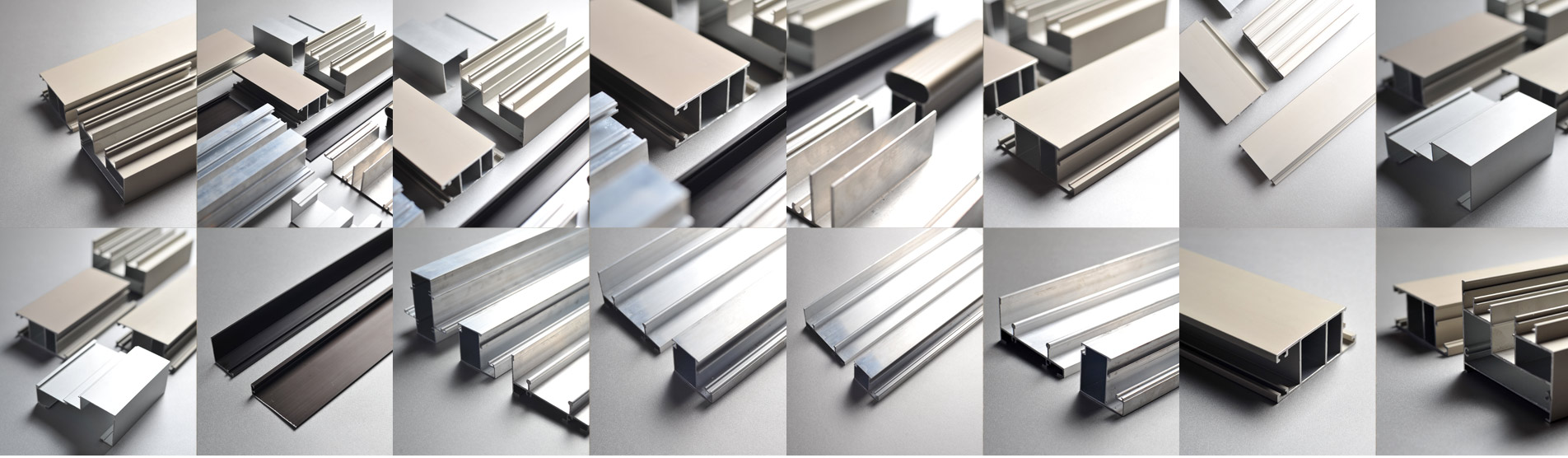

Special Custom Extruded Products

Aluvindo has the capability to design, produce and stock our customer’s own sections. Our extrusion manufacturing facilities can provide technical information along with in-house facilities to help design and produce extruded profiles specific to our customer’s needs.

Our extrusion manufacturing facilities produce profiles to the highest quality for use in numerous applications, such as architectural, automotive, marine, electrical, general engineering, road and transport.

All extrusions manufactured by Aluvindo are produced to the chemical composition, mechanical property and dimensional tolerances, following the international standards.

Alloy Range

Our alloy range includes 6005A, 6060, 6061, 6063, 6082, 6082B, 6101, 6106 and 6351.

Aluvindo’s Product Features

Aluminium seating from Aluvindo is lightweight and easily fabricated, offering substantial savings on installation costs.

Aluvindo aluminium is long lasting and is able to withstand the harsh elements, making it particularly suitable humid areas. Aluvindo aluminium requires minimal maintenance and will not stain, crack, warp, rust or splinter and does not require painting.

Aluvindo aluminum features smooth natural finishes giving the possibility of even better additional finishing process.

Varying measurement are available to accommodate our customers.

Aluvindo’s Product Facility

Added service for product finishes are available upon your request. Further to Aluvindo’s traditional anodized and powder coated finishes, various techniques and our range of finishing options ensures your extrusions can be easily matched to your project. Aluvindo is here help to make your job easier and efficient with these wide range of finishing choices.

Knurling

Application of non-slip surface to extrusions and product edge de-burring.

Anodizing

Controlled oxidation of the aluminum surface by immersion into a dilute sulphuric acid.

Powdercoating

Paint powder applied electrostatically and then cured under heat to allow it to flow and form a surface coating

Drilling

A cutting process that uses a drill bit to cut or enlarge a hole

Cut Back

An off line saw used to recut the extrusion to less than a standard length

Slotting & Punching

Toolage used to “punch” a hole in typically a window or door extrusion

Pile Installation

Mechanically install requested pile to an extrusion.

Precision Cutting

Cut back to less than standard extrusion tolerances.

Mitre Saw Cut

Saw used to make accurate cross cuts.